HY3351LT differential pressure direct Mounted Diaphragm Seal pressure level transmitter designed for industrial level measurement applications.It can be configured to provide intergrated solutions for a broad range of pressure and level measurement applications.

FEATURES

◆High-stability pressure sensor

◆Updating time of output current in 200 ms

◆Improved performance, increased accuracy and greater stability Two years stability of 0.15%

0.1% accuracy

◆Parameter setting by keypad directly

◆4-20 mA output plus direct digital HART communication Automatic zero calibration by push-button

◆Explosion proof and weather proof housing

◆Strong transient voltage resistance to protect terminal module

SPECIFICATIONS

Process Fluid | Liquid, gas or air(For gas and air measue pressure only) |

Applications | Liquid Level, Differential Pressure, Gauge Pressure, Absolute Pressure |

Measuring Range | 0 - 6.0 kPa ~ 0 - 40 kPa (Minimum) 0 - 4.0 MPa ~ 0 - 20.0 MPa (Maximum) |

Accuracy | +/- 0.1% of span |

Stability | +/-0.15% of URL for 2 years |

Working Temperature | -40 to +250 °C |

Max. Pressure | 40 MPa (Dependent on flange rating) |

Material | Flange/Adapter : Carbon Steel / Stainless Steel 304 /Stainless Steel 316 |

Diaphragm : Stainless Steel 316L / Hastelloy B / Hastelloy C / Monel / Tantalum | |

Bolts & Nuts : Carbon Steel / Stainless Steel 316 | |

Name / Tag Plate : Stainless Steel 304 / Stainless Steel 316 | |

Converter Housing : Low copper cast aluminum alloy with polyurethane, light blue paint | |

Fill Fluid : Silicone / High Temperature Silicone Fluorine Oil / Vegetable Oil | |

Protection Class | IP67 (Standard) Intrinsically Safe EEx ia IIC T5 (Standard) Explosion proof Ex D IIB T5 |

Display | 5 Digits programmable & 0-100% Bargraph |

Display Unit | Standard 22 different engineering unit 5 Digits programmable for special unit |

Keypad | 3 internal keys for programming and output setting |

Current Output | 4 - 20 mA 2 wires with Hart Signal (Compatible) Load : Rohm=(Vdc-9)*50 |

Power Supply | 9 - 32 VDC |

Digital Communication | Hart Protocol |

Damping | 0 - 32 seconds |

Response Time | 100 mS |

Turn on Time | 2 Seconds with minimum damping |

Zero Calibration | Automatic calibration by push-button |

Cable Entry | 1/2" NPT(Female) / M20 Conduit Threads |

Temperature Effect | +/-0.18% ~ +/-0.5% of span per 20 °C |

EMI/RFI Effect | Follow SAMA PMC 33.1 from 20 to 1000 MHz and for field strengths up to 30 V/m |

Process connection | High Pressure Side : 1-1/2", 2", 3", 4" Flanges ANSI / DIN / JIS / Tri-Clamp Extended Diaphragm : 2", 4", 6" length Low Pressure Side : 1/4" - 18 NPT , 1/2" - 14 NPT |

Ambient Temperature | -25 to +85 °C |

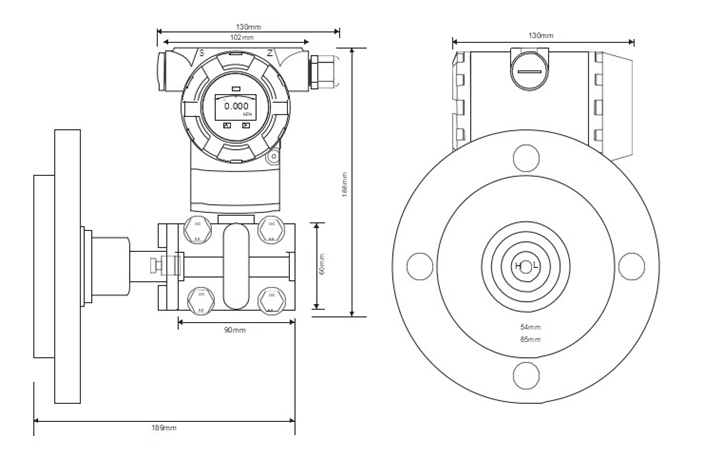

Dimensions | 102 mm (W) * 188 mm (H) * 189 mm (D) |

Weight | 8 - 15 Kg |

MEASURING RANGE

Code | Pressure Range | Transmitter | |||||

Low Range | High Range | Low Range | High Range | Differential Pressure | Level Pressure | Absolute Pressure | |

4 | 0 - 6.0 kPa | 0 - 40 kPa | 0 - 611.82 mmH2O | 0 - 4078 mmH2O |

◆ |

◆ |

◆ |

0 - 60 mbar | 0 - 400 mbar | 0 - 24.088 InH2O | 0 - 160.6 InH2O | ||||

0 - 0.87 psi | 0 - 5.802 psi | 0 - 0.061 Kg/cm2 | 0 - 0.408 Kg/cm2 | ||||

5 | 0 - 40 kPa | 0 - 200 kPa | 0 - 4.079 MH2O | 0 - 20.39 MH2O |

◆ |

◆ |

◆ |

0 - 400 mbar | 0 - 2000 mbar | 0 - 160.6 InH2O | 0 - 802.9 InH2O | ||||

0 - 5.802 psi | 0 - 29.0 psi | 0 - 0.408 Kg/cm2 | 0 - 2.039 Kg/cm2 | ||||

6 | 0 - 160 kPa | 0 - 1000 kPa | 0 - 16.32 MH2O | 0 - 101.97 MH2O |

◆ |

◆ |

◆ |

0 - 1.6 bar | 0 - 10 bar | 0 - 642.3 InH2O | 0 - 4014 InH2O | ||||

0 - 23.21 psi | 0 - 145 psi | 0 - 1.632 Kg/cm2 | 0 - 10.197 Kg/cm2 | ||||

7 | 0 - 400 kPa | 0 - 2500 kPa | 0 - 40.79 MH2O | 0 - 254.9 MH2O |

◆ |

◆ |

◆ |

0 - 4.0 bar | 0 - 25 bar | 0 - 1605 InH2O | 0 - 10036 InH2O | ||||

0 - 58.02 psi | 0 - 362.6 psi | 0 - 4.079 Kg/cm2 | 0 - 25.49 Kg/cm2 | ||||

8 | 0 - 1.6 MPa | 0 - 8.0 MPa | 0 - 163.1 MH2O | 0 - 815.76 MH2O |

◆ | ||

0 - 16 bar | 0 - 80 bar | 0 - 6423.4 InH2O | 0 - 32117 InH2O | ||||

0 - 232.1 psi | 0 - 1160.3 psi | 0 - 16.32 Kg/cm2 | 0 - 81.578 Kg/cm2 | ||||

9 | 0 - 4.0 MPa | 0 - 20 MPa | 0 - 407.9 MH2O | 0 - 2039.4 MH2O |

◆ | ||

0 - 40 bar | 0 - 200 bar | 0 - 16059 InH2O | 0 - 80292.6 InH2O | ||||

0 - 580.2 psi | 0 - 2901 psi | 0 - 40.79 Kg/cm2 | 0 - 203.94 Kg/cm2 | ||||

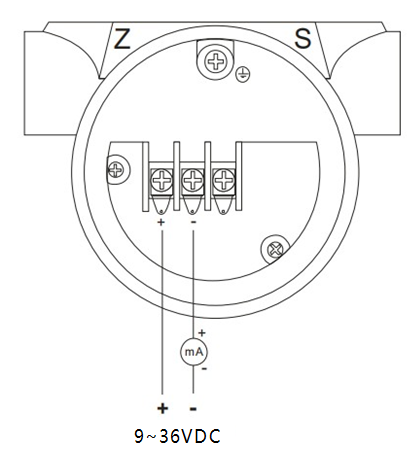

WIRING DIAGRAM

DIMENSIONS

ORDER SELECTION

Item | Code | Discription |

HY3351LT | Smart Prssure Level Transmitter | |

Range | 3 | 0-4~7.5 Kpa |

4 | 0~37.4 Kpa | |

5 | 0~186.8 Kpa | |

6 | 0~690 Kpa | |

7 | 0~2068 Kpa | |

Output | H | 4-20mA, HART Protocol, Linear output |

Diaphragm Material/ Fill Fluid | 2 | Stainless Steel 316L Silicone Oil |

3 | Hastelloy C Silicone Oil | |

A | Stainless Steel 316L Fluorine oil | |

Drain hole | B | Back of process flange or none |

U | Process flange side upper | |

L | Process flange side lower | |

Wetted O-ring Material | 7 | Buna-N (NBR) |

6 | Viton (FKM) (Temperature ≥-20℃) | |

5 | Low Temperature Viton (FKM-GFLT) | |

Cable Entry | M | M20*1.5 |

N | 1/2”NPT | |

Process Connection | N21 | 2'' ANSI 150# |

N23 | 2'' ANSI 300# | |

N26 | 2'' ANSI 600# | |

N31 | 3'' ANSI 150# | |

N33 | 3'' ANSI 300# | |

N36 | 3'' ANSI 600# | |

N41 | 4'' ANSI 150# | |

N43 | 4'' ANSI 300# | |

G51 | DN50 PN1.6MPa | |

G54 | DN50 PN40Mpa | |

G56 | DN50 PN6.4Mpa | |

G81 | DN80 PN1.6MPa | |

G84 | DN80 PN4.0Mpa | |

G86 | DN80 PN6.4Mpa | |

G11 | DN100 PN1.6MPa | |

G14 | DN100 PN4.0Mpa

| |

O | Others as per request

| |

Flange Diaphragm Material | A | Stainless steel 316L |

B | Hastelloy C | |

C | Tantalum | |

E | PFA coating | |

Insert Tube Length | 0 | 0 |

1 | 50mm | |

2 | 100mm | |

3 | 150mm | |

Optional | F | Intrinsically safe type, Flameproof (Exd IIC T4~T6) |

S | Intrinsically safe (Exia IIC T4~T6) | |

V | Stainless steel drain valve or screw (2pcs) | |

N | 1/2'' NPT female waist flange (2sets) | |

NM | 1/2'' NPT-M20*1.5-Φ14 pressure pipe (2sets) | |

M | M20*1.5 male thread T joint (2sets) | |