HY3351RD REMOTE DIAGRAM SEAL PRESSURE LEVEL TRANSMITTER is a diaphragm seal transmitter, which designed for the high-viscosity/ granular/ high-temp./ high-corrosivity situations.

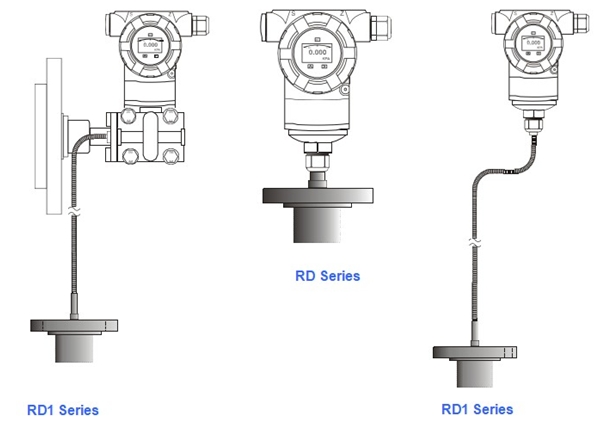

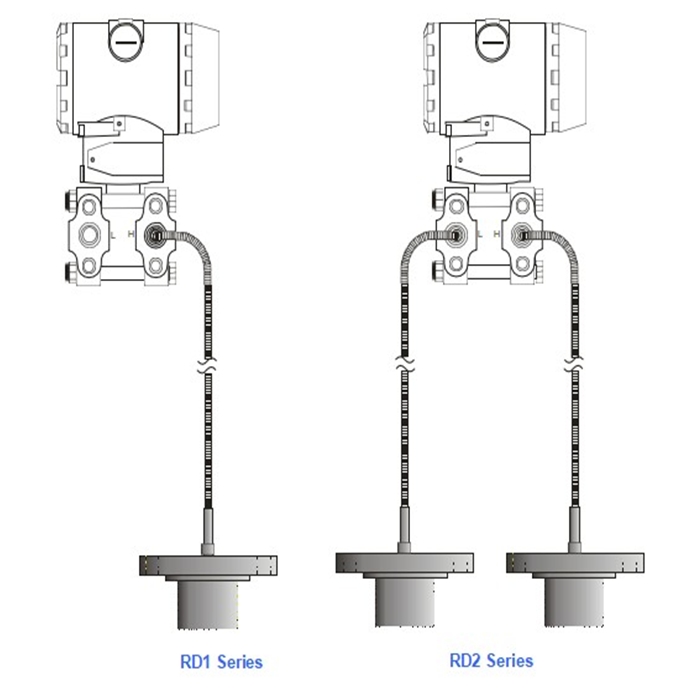

The diaphragm seal assembles pressure / DP transmitter to form direct-mount / capillary-connections styles.

CONTACT US

FEATURES

![]() The maximum temperature comes up to 280 oC

The maximum temperature comes up to 280 oC![]() Multiple connection modes - Flange style / Tri-Clamp style

Multiple connection modes - Flange style / Tri-Clamp style![]() Multiple diaphragms/alternative connection material

Multiple diaphragms/alternative connection material![]() Vegetable oil can be used for fill fluid for food industry

Vegetable oil can be used for fill fluid for food industry![]() Extreme hot and cold temperature

Extreme hot and cold temperature![]() Stainless Steel with PPC coating capillary

Stainless Steel with PPC coating capillary ![]() IDF Tri-Clamp or union screw connection for food industry

IDF Tri-Clamp or union screw connection for food industry![]() Oil-free treatment & water-free treatment

Oil-free treatment & water-free treatment![]() Fast and dynamic response

Fast and dynamic response![]() Improved performance, increased accuracy and great stability

Improved performance, increased accuracy and great stability

SPECIFICATIONS

Process Fluid | Liquid, Gas or Vapor |

Application | Liquid Level, Differential Pressure, Gauge Pressure, Absolute Pressure |

Measuring Range | 0 - 6.0 kPa ~ 0 - 40 kPa (Minimum) 0 - 4.0 MPa ~ 0 - 20.0 MPa (Maximum) |

Material | Flange : Carbon stee Stainless Steel 304 Stainless Steel 316 Diaphragms : Stainless Steel 316L Hastelloy B Hastelloy C Tantalum PTFE-coated Tantalum Diaphragm Capillary Stainless Steel with PTFE coating |

Flange Size | 40mm, 50mm, 80mm, 100mm 1-1/2", 2", 3", 4" |

Process Connection | Flange |

Flange Rating | JIS 10K / JIS 20K / JIS 40K ANSI 150# / ANSI 300# / ANSI 600# DIN PN10 / PN16 / PN25 / PN40 Tri Clamp (DIN32676 / ISO2852) |

Extension Length | 2", 3", 4" |

Installation Style | Direct-mount: RD One-sided Capillary: RD1 Two-sided Capillaries: RD2 |

Capillary Length | 1.0 M ~ 10 M |

Max. Temperature | Direct-Mount : -20 to 80 °C Remote Diaphragm : -40 to 280 °C |

Max. Pressure | 8.0MPa |

Fill Fluid and Maximum | Silicone (Max. Temperature 130 °C) |

Temperature | HT Silicone (Max. Temperature 280 °C) Fluorine (Max. Temperature 160 °C) Vegetable Oil (Max. Temperature 130 °C) |

Ambient Temperature | +/-0.18% ~ +/-0.5% of span per 20 °C Effect |

Time Response | Less than 1.12 seconds |

Options | Water-free Treatment :Wetted parts are water-free treated in manufacturing Oil-free Treatment :Wetted parts are oil-free treated in manufacturing |

Stability | +/-0.15% of URL for 2 years |

Accuracy | +/-0.1% of Span |

RANGE

Direct-Mount Diaphragm | Min. Range | Max. Range | Min. Range | Max. Range |

Pressure Transmitter RD Series | 0 - 10 kPa | 0 - 100 MPa | 0 - 1019.7 mmH20 | 0 - 10197 MH2O |

0 - 100 mbar | 0 - 1000 bar | 0 - 40.15 InH2O | 0 - 401463 InH2O | |

0 - 1.45 psi | 0 - 14504 psi | 0 - 0.1 Kg/cm2 | 0 - 1020 kg/cm2 | |

Remote Diaphragm Seal | Min. Range | Max. Range | Min. Range | Max. Range |

Pressure Transmitter RD1 Series | 0 - 6.0 kPa | 0 - 8.0 MPa | 0 - 611.82 mmH2O | 0 - 815.76 MH2O |

0 - 60 mbar | 0 - 80 bar | 0 - 24.088 InH2O | 0 - 32117 InH2O | |

0 - 0.87 psi | 0 - 1160.3 psi | 0 - 0.061 Kg/cm2 | 0 - 81.578 Kg/cm2 | |

Differential Pressure Transmitter RD1 / RD2 Series | 0 - 6.0 kPa | 0 - 8.0 MPa | 0 - 611.82 mmH2O | 0 - 815.76 MH2O |

0 - 60 mbar | 0 - 80 bar | 0 - 24.088 InH2O | 0 - 32117 InH2O | |

0 - 0.87 psi | 0 - 1160.3 psi | 0 - 0.061 Kg/cm2 | 0 - 81.578 Kg/cm2 | |

Level Transmitter RD1 Series | 0 - 6.0 kPa | 0 - 8.0 MPa | 0 - 611.82 mmH2O | 0 - 815.76 MH2O |

0 - 60 mbar | 0 - 80 bar | 0 - 24.088 InH2O | 0 - 32117 InH2O | |

0 - 0.87 psi | 0 - 1160.3 psi | 0 - 0.061 Kg/cm2 | 0 - 81.578 Kg/cm2 |

FLANGE TABLES

Flange style | Dimension of Flange | Bolt | Flange style | Dimension of Flange | Bolt | ||||||

C | D | T | H | NO | C | D | T | H | NO | ||

1-1/2" JIS 10K | 105 | 140 | 16 | 19 | 4 | DN40 PN10 | 110 | 150 | 18 | 18 | 4 |

2" JIS 10K | 120 | 155 | 16 | 19 | 4 | DN50 PN10 | 125 | 165 | 20 | 18 | 4 |

3" JIS 10K | 150 | 185 | 18 | 19 | 8 | DN80 PN10 | 160 | 200 | 24 | 18 | 8 |

4" JIS 10K | 175 | 210 | 18 | 19 | 8 | DN100 PN 10 | 180 | 220 | 20 | 18 | 8 |

1-1/2" JIS 20K | 105 | 140 | 16 | 19 | 4 | DN40 PN16 | 110 | 150 | 18 | 18 | 4 |

2" JIS 20K | 120 | 155 | 16 | 19 | 4 | DN50 PN16 | 125 | 165 | 20 | 18 | 4 |

3" JIS 20K | 160 | 200 | 20 | 23 | 8 | DN80 PN16 | 160 | 200 | 24 | 18 | 8 |

4" JIS 20K | 185 | 225 | 22 | 23 | 8 | DN100 PN16 | 180 | 220 | 24 | 18 | 8 |

1-1/2" JIS 40K | 120 | 160 | 24 | 23 | 4 | DN40 PN25 | 110 | 150 | 18 | 18 | 4 |

2" JIS 40K | 130 | 165 | 26 | 19 | 8 | DN50 PN25 | 125 | 165 | 20 | 18 | 4 |

3" JIS 40K | 170 | 210 | 32 | 23 | 8 | DN80 PN25 | 160 | 200 | 24 | 18 | 8 |

4" JIS 40K | 205 | 250 | 36 | 25 | 8 | DN100 PN25 | 190 | 235 | 24 | 22 | 8 |

1-1/2" ANSI 150# | 98.6 | 127 | 18 | 15.7 | 4 | DN40 PN40 | 110 | 150 | 22 | 18 | 4 |

2" ANSI 150# | 120.7 | 152.4 | 19 | 19.1 | 4 | DN50 PN40 | 125 | 165 | 24 | 18 | 4 |

3" ANSI 150# | 152.4 | 190.5 | 24 | 19.1 | 4 | DN80 PN40 | 160 | 200 | 24 | 18 | 8 |

4" ANSI 150# | 190.5 | 228.6 | 24 | 19.1 | 8 | DN100 PN40 | 190 | 235 | 24 | 22 | 8 |

1-1/2" ANSI 300# | 114.3 | 155.4 | 24.6 | 22.4 | 4 | ||||||

2" ANSI 300# | 127 | 165.1 | 26.4 | 19.1 | 8 | ||||||

3" ANSI 300# | 168.1 | 209.6 | 32.4 | 22.4 | 8 | ||||||

4" ANSI 300# | 200.2 | 254 | 35.8 | 22.4 | 8 | ||||||

DIMENSIONS