HY3051TG direct mounted series pressure transmitter is a digital differential pressure transmitter designed for industrial pressure measurement applications.The HY3051TG can be configured for gauge pressure, absolue Pressure and vacuum solutions for industry applications.

CONTACT US

FEATURES

►Updating time of output current in 200 ms

►Improved performance, increased accuracy and greater stability

►Two years stability of 0.2%

►0.075% accuracy

►Parameter setting by keypad directly

►4-20 mA output plus direct digital HART communication

► Automatic zero calibration by press-button

►Explosion proof and weather proof housing

SPECIFICATIONS

Process Fluid | Liquid, Gas of Vapor |

Application | Absolute Pressure, Gauge Pressure |

Measuring Range | 0 - 10 kPa ~ 0 - 30 kPa (Minimum) 0 - 32.0 MPa ~ 0 - 100.0 MPa (Maximum) |

Accuracy | +/- 0.075% of span |

Stability | +/-0.15% of URL for 2 years |

Working Temperature | -25 to +95 °C |

Max. Pressure | 100 MPa |

Material | |

Connection : Stainless Steel 304 / Stainless Steel 316 | |

Diaphragm : Stainless Steel 316L / Hastelloy B / Hastelloy C / Monel / Tantalum | |

Name / Tag Plate | Stainless Steel 304 / Stainless Steel 316 |

Converter Housing | Low copper cast aluminum alloy withpolyurethane, light blue paint |

Protection Class | IP65 (Standard) Intrinsically Safe EEx ia IIC T5 (Standard) Explosion proof Ex D IIB T5 |

Display | 5 Digits programmable & 0-100% Bargraph |

Display Unit | Standard 22 different engineering unit 5 Digits programmable for special unit |

Keypad | 3 internal keys for programming and output setting |

Current Output | 4 - 20 mA 2 wires with Hart signal (Compatible) Load : Rohm=(Vdc-9)*50 |

Power Supply | 9 - 36 VDC |

Damping | 0 - 32 seconds |

Response Time | 200 mS |

Mounting | Direct mounting or Bracket on 2" Pipe |

Humidity Limit | 0 to 100% Relative Humidity |

Turn on Time | 2 Seconds with minimum damping |

Zero Calibration | Automatic zero calibration by press-button |

Cable Entry | M20 Conduit Threads / 1/2" NPT (Female) |

Temperature Effect | +/-0.18% ~ +/-0.5% of span per 20 °C |

Vibration Effect | +/-0.05% of URL per g to 200 Hz in any axis |

EMI/RFI Effect | Follow SAMA PMC 33.1 from 20 to 1000 MHz and for field strengths up to 30 V/m |

Process Connection | 1/4" - 18 NPT 1/2" - 14 NPT(with adapter) |

Ambient Temperature | -25 to +80 °C |

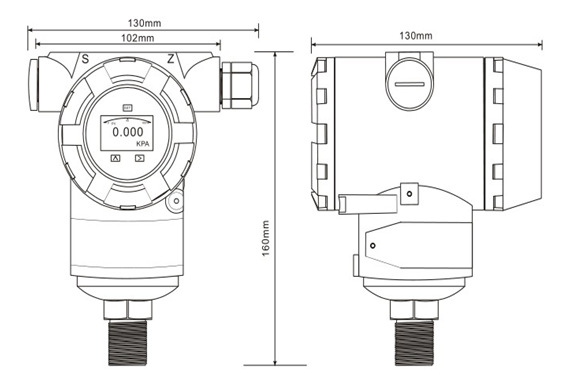

Dimensions | 102 mm ( W ) * 160 mm ( H ) * 130 mm (D) |

Weight | 1.3 Kg |

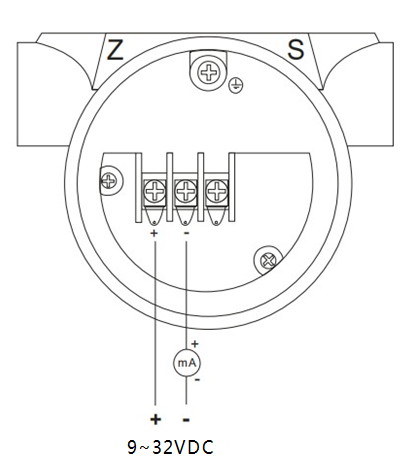

WIRING DIAGRAM

DIMENSIONS

Order Code:

Item | Code | Specification |

HY3051TG | Gauge Pressure Transmitter | |

HY3051TA | Absolute Pressure Transmitter | |

Measurement Range | 3 | 0-1.5~7.5 Kpa |

4 | 0~37.4 Kpa | |

5 | 0~186.8 Kpa | |

6 | 0~690 Kpa | |

7 | 0~2068 Kpa | |

8 | 0~6890 Kpa | |

9 | 0~20680 Kpa | |

0 | 0~41370 Kpa | |

Output | S | 4-20mA, HART Protocol, Linear output |

Diaphragm Material | 2 | Stainless Steel 316L |

3 | Hastelloy C | |

Fill Fluid | 2 | Silicone Oil |

2 | Fluorine oil | |

Process Connection | D | 1/2'' NPT F |

A | M20*1.5 | |

B | 1/2'' NPT M | |

C | 1/2'' G | |

D | Customizable | |

Cable Entry | 1 | M20*1.5 |

Mounting Bracket | B00 | None |

B15 | Tube-type Flat Bracket (carbon steel) | |

B16 | Wall mounting bracket (carbon steel) | |

B17 | Tube-type Flat Bracket (stainless steel) | |

Optional | B18 | Wall mounting bracket (stainless steel) |

d | Intrinsically safe type, Flameproof (Exd IIC T4~T6) | |

i | Intrinsically safe (Exia IIC T4~T6) | |

M3 | LCD display | |

K1 | Degreasing treatment | |

L1 | Hanging tag | |

5C6 | Lightning protection | |

Previous: Flush Pressure Transmitter