The sanitary liquid turbine flow meter is specifically designed for measurement of food liquids like milk, cream, juice of various fruits, pharma liquids etc. It is available with compact or remote version of transmitter can be in stalled either horizontally or vertically with a variety of optional end-fittings to meet your requirements.

Specifications:

Medium | Non Corrosive Liquid( milk,juice,cream etc) |

Nominal Diameter | DN4-DN100 |

Accuracy Level | ±1.0%R 0.5% Selectable |

Repeatablility | ±0.1% |

Turndown Ratio | 1:10,1:15,1:20 |

Material | Body/Rotor Support:SS304(SS316L optional) |

Impeller:Double Phase Steel | |

Bearing and Shaft: Tungsten Carbide | |

Working Condition | Medium Temperature:-20℃~+120℃ (Max Customize to150℃) |

Ambient Temperature:-20℃~+55℃ | |

Rated Humidity:5%~90% | |

Ambient Pressure:86KPa~106KPa | |

Power | 24VDC |

3V 10AH lithium battery. | |

Consumption | 24VDC power:<1W |

Battery:≤1W,lifetime>3yrs | |

Signal Output | Pulse,4-20mA,Switch Signal. |

DIgital Communication | RS485,MODBUS,HART,PROFIBUS-DP |

Signal wire joint | Hausman joint/Inner screw M20*1.5 or customized |

Explosion Proof Grade | ExdIIBT6/ExiaIICT4 |

Degree of Protection | IP65 or Higher |

Flow Range

Diameter (mm) | Standard Range (m3/h) | Extended Range (m3/h) |

4 | 0.04-0.25 | 0.04-0.4 |

5 | 0.1-0.6 | 0.06-0.6 |

10 | 0.2-1.2 | 0.15-1.5 |

15 | 0.6-6 | 0.4-8 |

20 | 0.8-8 | 0.45-9 |

25 | 1-10 | 0.5-10 |

32 | 1.5-15 | 0.8-15 |

40 | 2-20 | 1-20 |

50 | 4-40 | 2-40 |

65 | 7-70 | 4-70 |

80 | 10-100 | 5-100 |

100 | 20-200 | 10-200 |

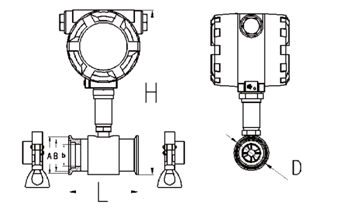

Dimensions:

Tri-Clamp Connection

Unit:mm

OD | L | D | A | B | b | H | |||

Pulse type | Ex Pulse | EX 4-20mA | LCD display | ||||||

4 | 50 | 50.5 | 46 | 40.5 | 4 | 145 | 150 | 150 | 210 |

6 | 6 | 145 | 150 | 150 | 210 | ||||

10 | 10 | 145 | 150 | 150 | 210 | ||||

15 | 100 | 15 | 155 | 160 | 160 | 225 | |||

20 | 20 | 160 | 160 | 160 | 225 | ||||

25 | 25 | 160 | 165 | 165 | 230 | ||||

32 | 120 | 32 | 165 | 165 | 165 | 230 | |||

40 | 140 | 64 | 59 | 110 | 40 | 175 | 180 | 180 | 245 |

50 | 150 | 78 | 73.5 | 125 | 50 | 185 | 190 | 190 | 255 |

65 | 170 | 91 | 86 | 145 | 65 | 205 | 205 | 205 | 270 |

80 | 200 | 106 | 100.5 | 160 | 80 | 215 | 220 | 220 | 285 |

100 | 220 | 119 | 113 | 180 | 100 | 235 | 240 | 240 | 305 |

Order Selection:

Model | Code | Description | ||||||||

LWGY |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

Liquid turbine flow meter | |

Diameter |

XXXX | Standard for diameter 0006:DN6;0015: DN15 0100:DN100 | ||||||||

Temerature | N | Normal type, less than 80C | ||||||||

C | High temperature type | |||||||||

Converter | N | Pulse output without LCD display | ||||||||

A | 4-20mA output without LCD dispaly | |||||||||

B | LCD display without output | |||||||||

C | LCD display with 4-20mA output | |||||||||

R | LCD display with RS485 | |||||||||

H | LCD display with Hart | |||||||||

Signal output | 0 | No output | ||||||||

1 | Pulse | |||||||||

2 | 4-20mA | |||||||||

Flange material | 2 | SS202 | ||||||||

4 | SS304 | |||||||||

6 | SS316 | |||||||||

Power supply | 0 | 24VDC | ||||||||

1 | Battery (no output) | |||||||||

communication | 0 | NO communication | ||||||||

1 | Modbus RS485 | |||||||||

2 | Hart | |||||||||

C | Tri-Clamp connection | |||||||||

Body material | S4 | Stainless steel 304 | ||||||||

S6 | Stainless Steel 316 | |||||||||

Previous: LWGY Liquid Turbine Flow Meter

Next: No more