LWGY series turbine flowmeter is a kind of speed flowmeter. The sensor of turbine flow meter has the advantages of simple structure, lightweight, high precision, good reproducibility and quick response. It is widely used in petroleum, chemical industry, metallurgy, water supply, papermaking and other industries. It is the best choice for flow measurement and energy saving.

Specifications:

Medium | Non Corrosive Liquid( Water,Ethanol,Diesel etc) |

Nominal Diameter | DN4-DN200 |

Rated Pressure | 1.6MPa~6.3MPa Max Customize to 42MPa |

Accuracy Level | ±1.0%R 0.5% Selectable |

Repeatablility | ±0.1% |

Turndown Ratio | 1:10,1:15,1:20 |

Material | Body/Rotor Support:SS304(SS316L optional) |

Impeller:Double Phase Steel | |

Bearing and Shaft: Tungsten Carbide | |

Working Condition | Medium Temperature:-20℃~+120℃ (Max Customize to150℃) |

Ambient Temperature:-20℃~+55℃ | |

Rated Humidity:5%~90% | |

Ambient Pressure:86KPa~106KPa | |

Power | 24VDC |

3V 10AH lithium battery. | |

Consumption | 24VDC power:<1W |

Battery:≤1W,lifetime>3yrs | |

Signal Output | Pulse,4-20mA,Switch Signal. |

DIgital Communication | RS485,MODBUS,HART,PROFIBUS-DP |

Signal wire joint | Hausman joint/Inner screw M20*1.5 or customized |

Explosion Proof Grade | ExdIIBT6/ExiaIICT4 |

Degree of Protection | IP65 or Higher |

Flow Range

Diameter (mm) | Standard Range (m3/h) | Extended Range (m3/h) |

4 | 0.04-0.25 | 0.04-0.4 |

5 | 0.1-0.6 | 0.06-0.6 |

10 | 0.2-1.2 | 0.15-1.5 |

15 | 0.6-6 | 0.4-8 |

20 | 0.8-8 | 0.45-9 |

25 | 1-10 | 0.5-10 |

32 | 1.5-15 | 0.8-15 |

40 | 2-20 | 1-20 |

50 | 4-40 | 2-40 |

65 | 7-70 | 4-70 |

80 | 10-100 | 5-100 |

100 | 20-200 | 10-200 |

125 | 25-250 | 13-250 |

150 | 30-300 | 15-300 |

200 | 80-800 | 40-800 |

Dimensions:

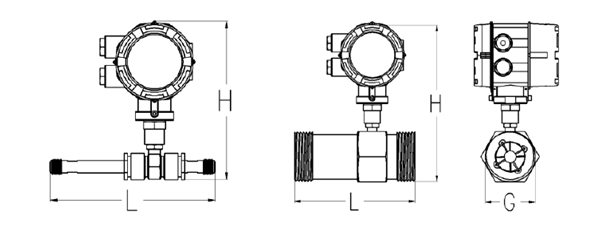

1.0 Thread connection:

Unit:mm

OD | L | H | Thread | |||

Pulse type | Ex Pulse | EX 4-20mA | LCD display | |||

4 | 225 | 140 | 145 | 145 | 210 | G1/2 |

6 | 225 | 140 | 145 | 145 | 210 | G1/2 |

10 | 345 | 145 | 150 | 145 | 210 | G1/2 |

15 | 75 | 745 | 150 | 150 | 215 | G1 |

20 | 80 | 150 | 155 | 155 | 220 | G1 |

25 | 100 | 155 | 160 | 160 | 225 | G1-1/4 |

32 | 140 | 175 | 180 | 180 | 245 | G2 |

40 | 140 | 180 | 185 | 180 | 250 | G2 |

50 | 150 | 185 | 190 | 190 | 255 | G2-1/2 |

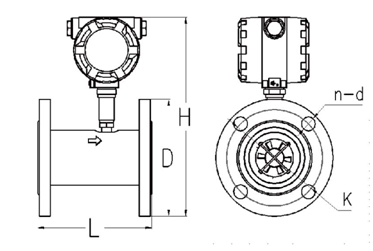

2.0 Flange connection

Unit:mm

OD | L | D | K | H | d | n | Pressure | |||

Pulse type | Ex Pulse | EX 4-20mA | LCD display | |||||||

15 | 75 | 95 | 65 | 175 | 180 | 180 | 245 | 14 | 4 | 2.5Mpa |

20 | 80 | 105 | 75 | 185 | 190 | 190 | 255 | 14 | 4 | |

25 | 100 | 115 | 85 | 200 | 195 | 195 | 260 | 14 | 4 | |

32 | 140 | 140 | 100 | 210 | 215 | 215 | 275 | 18 | 4 | |

40 | 140 | 150 | 110 | 195 | 220 | 220 | 285 | 18 | 4 | |

50 | 150 | 165 | 125 | 230 | 235 | 235 | 295 | 18 | 4 | |

65 | 170 | 185 | 145 | 255 | 260 | 260 | 325 | 18 | 4 | 1.6Mpa |

80 | 200 | 200 | 160 | 260 | 265 | 265 | 330 | 18 | 8 | |

100 | 220 | 220 | 180 | 285 | 285 | 285 | 350 | 18 | 8 | |

125 | 250 | 250 | 210 | 310 | 315 | 315 | 380 | 18 | 8 | |

150 | 300 | 285 | 240 | 345 | 345 | 345 | 410 | 22 | 8 | |

200 | 360 | 340 | 295 | 395 | 400 | 400 | 465 | 22 | 12 | |

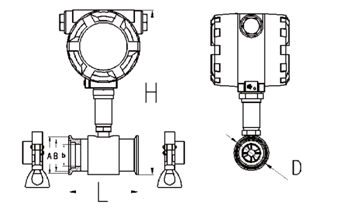

Tri-Clamp Connection

Unit:mm

OD | L | D | A | B | b | H | |||

Pulse type | Ex Pulse | EX 4-20mA | LCD display | ||||||

4 | 50 | 50.5 | 46 | 40.5 | 4 | 145 | 150 | 150 | 210 |

6 | 6 | 145 | 150 | 150 | 210 | ||||

10 | 10 | 145 | 150 | 150 | 210 | ||||

15 | 100 | 15 | 155 | 160 | 160 | 225 | |||

20 | 20 | 160 | 160 | 160 | 225 | ||||

25 | 25 | 160 | 165 | 165 | 230 | ||||

32 | 120 | 32 | 165 | 165 | 165 | 230 | |||

40 | 140 | 64 | 59 | 110 | 40 | 175 | 180 | 180 | 245 |

50 | 150 | 78 | 73.5 | 125 | 50 | 185 | 190 | 190 | 255 |

65 | 170 | 91 | 86 | 145 | 65 | 205 | 205 | 205 | 270 |

80 | 200 | 106 | 100.5 | 160 | 80 | 215 | 220 | 220 | 285 |

100 | 220 | 119 | 113 | 180 | 100 | 235 | 240 | 240 | 305 |

Order Selection:

Model | Code | Description | ||||||||

LWGY |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

Liquid turbine flow meter | |

Diameter |

XXXX | Standard for diameter 0006:DN6;0015: DN15 0100:DN100 | ||||||||

Temerature | N | Normal type, less than 80C | ||||||||

C | High temperature type | |||||||||

Converter | N | Pulse output without LCD display | ||||||||

A | 4-20mA output without LCD dispaly | |||||||||

B | LCD display without output | |||||||||

C | LCD display with 4-20mA output | |||||||||

R | LCD display with RS485 | |||||||||

H | LCD display with Hart | |||||||||

Signal output | 0 | No output | ||||||||

1 | Pulse | |||||||||

2 | 4-20mA | |||||||||

Flange material | 2 | SS202 | ||||||||

4 | SS304 | |||||||||

6 | SS316 | |||||||||

Power supply | 0 | 24VDC | ||||||||

1 | Battery (no output) | |||||||||

communication | 0 | NO communication | ||||||||

1 | Modbus RS485 | |||||||||

2 | Hart | |||||||||

connection | F | Flange connection | ||||||||

T | Thread connection | |||||||||

C | Tri-Clamp connection | |||||||||

Body material | S4 | Stainless steel 304 | ||||||||

S6 | Stainless Steel 316 | |||||||||

Previous: No more