HY 3051H-DP intelligent differential pressure transmitter is a well-developed high performance pressure transmitter based on the international leading technology, adopting the world advanced monocrystalline silicon pressure sensor technology and the patented packaging process. This product adopts the patented double overload protection diaphragm design, with the internal circuit surge protection design, and can accurately measure the gauge pressure, flow, vacuum degree, liquid level and density.

Features

■ Advanced monocrystalline silicon differential pressure sensor adopted

■ Wide pressure range covering 0-0.2kPa~

3MPa

■ Double-wire mode, 4~20mA analog output, HART® protocol digital communication option

■ Intelligent LCD gauge outfit with backlight

■ With both the remote transmission and the local zero and pressure range adjustment

■ Complete varieties, high accuracy, good stability,

■ Isolation ex-proof housing structure, strong resistance to the frequency conversion interference

■ High static pressure, high overload protection

■ Patented double overload protection diaphragm design

■ Lightning protection circuit design

Applications and industries

■ Process control fields for the industries such as petroleum, chemical industry, metallurgy, electricity,

food, papermaking, medicine, machine manufacturing, scientific experiment and military aviation etc.

Performance parameters | |||

Pressure range | -100kPa…0~0.2kPa…3MPa | ||

Pressure reference | Gauge pressure, Differential pressure | ||

Supply & output | 4~20mA, 4~20mA+HART® protocol (10.5V~36V, usually 24V) | ||

Accuracy | ±0.05%FS; ±0.1%FS (typ.) | ||

Zero temp. coefficient | ±0.25%FS/55℃ | ||

Full span temperature effect | ±0.5%FS/55℃ | ||

Ambient temperature | -30℃~80℃; with LCD gauge outfit -30℃~70℃ | ||

Medium temp. | -40℃~104℃ | ||

Storage temp. | -40℃~85℃ | ||

Insulation resistance | ≥100MΩ/500VDC (200MΩ/250VDC) | ||

Protection grade | IP65 | ||

Ex-proof grade | Exd II BT6 Gb | ||

Static pressure range | 16MPa, 25MPa, 40MPa | ||

Overpressure limitation | 16MPa | ||

Long-term stability | ±0.2%FS/year | ||

Structural performance | |||

Diaphragm material | 316L (316L sprayed with PTFE, Hastelloy C, tantalum, only suitable for the flush series of products with flange) | ||

Exhaust/Drain valve | SS316 | ||

O-ring | Chemigum (contact with the measurement medium) | ||

Filling liquid | Silicon oil | ||

Flange and clamp block | SS304 | ||

Housing material | Die-casting aluminum epoxy resin coating | ||

Electrical connection | M20×1.5 (Female), NPT1/2 (Female) | ||

Pressure connection | M20×1.5 (Male) with welded pipe, 304 tri-valve set M20×1.5 (Male) with welded pipe | ||

NPT1/4 (Female), 304 tri-valve set NPT1/4 (Female), NPT1/2 (Male), NPT1/2 (Female) | |||

G1/2 (Male) with welded pipe, G1/4 (Male) | |||

Weight | 3.5kg (not including the optional accessory) | ||

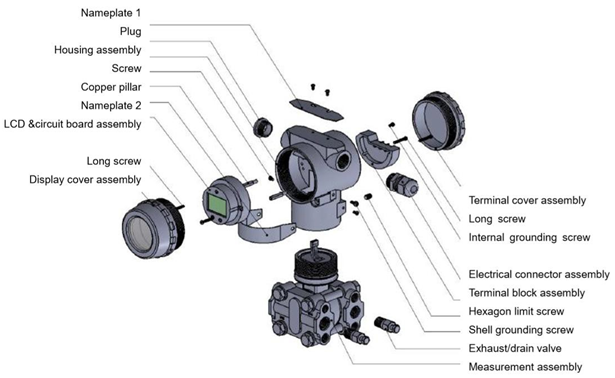

Component Digram |

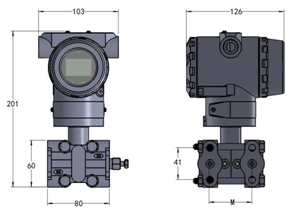

Dimensions |

Unit: mm

M:54 (3,4,5E) 54.5 (6E) 55(7,8E)

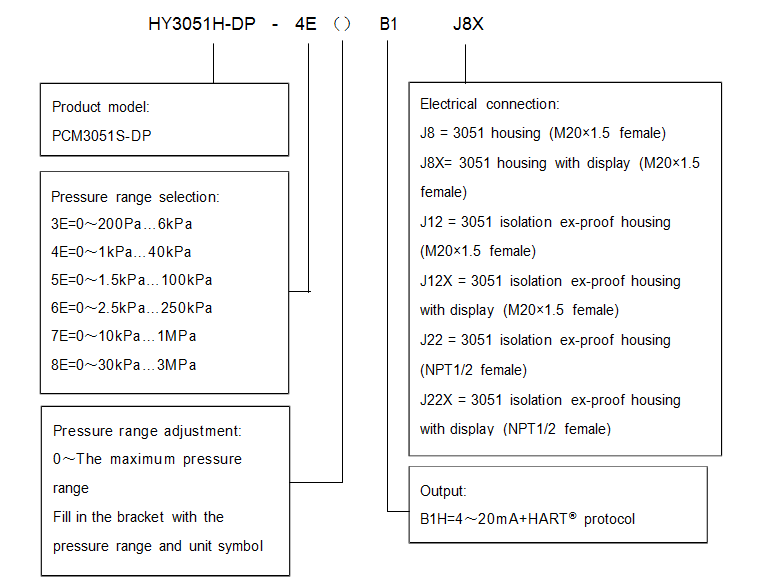

Order Selection |

Previous: Capacitive Pressure Sensor---Smar Sensor

Next: No more