Thermal Type Gas Mass Flowmeter utilizes the principle of heat exchange to measure fluid -flow. This meter employs method of constant temperature difference to accurately measure gas mass flow, and it has the advantages of small size, the high degree of digitization, easy installation, accurate measurement, etc.

CONTACT USFeatures

Measuring the mass flow or volume flow of gas

Do not need to do temperature and pressure compensation in principle with accurate measurement and easy operation.

Wide range: 0.5Nm/s~100Nm/s for gas. The meter also can be used for gas leak detection

Good vibration resistance and long service life. No moving parts and pressure sensor in transducer, no vibration influence

on the measurement accuracy.

Easy installation and maintenance. If the conditions on site are permissible, the meter can achieve a hot-tapped installation

and maintenance. (Special order of custom-made)

Digital design, high accuracy and stability

Configuring with RS485 or HART interface to realize factory automation and integration

Description | Specifications |

Measuring Medium | Various gases (Except the acetylene) |

Pipe Size | DN10~DN4000mm |

Velocity | 0.1~100 Nm/s |

Accuracy | ±1~2.5% |

Working Temperature | Sensor: -40℃~+220℃ Transmitter: -20℃~+45℃ |

Working Pressure | Insertion Sensor: medium pressure≤ 1.6MPa Flanged Sensor: medium pressure≤ 1.6MPa Special pressure please contact us |

Power Supply | 24VDC or 220VAC |

Response Time | 1s |

Output | 4-20mA (optoelectronic isolation, maximum load 500Ω), Pulse, RS485

(optoelectronic isolation) and HART |

Alarm Output | 2 line Relay, Normally Open state, 3A/30V/DC |

Sensor Type | Standard Insertion, Hot-tapped Insertion and Flanged |

Construction | Compact and Remote |

Pipe Material | Carbon steel, stainless steel, plastic, etc |

Display | 4 lines LCD

Mass flow, Volume flow in standard condition, Flow totalizer, Velocity, etc. |

Protection Class | IP65 |

Sensor Housing

Material |

Stainless steel (316) |

Mechanical Construction

Appearance

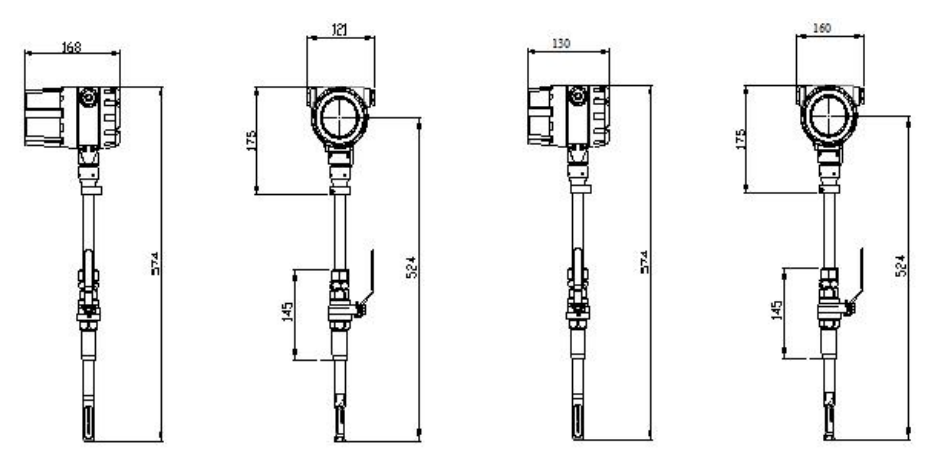

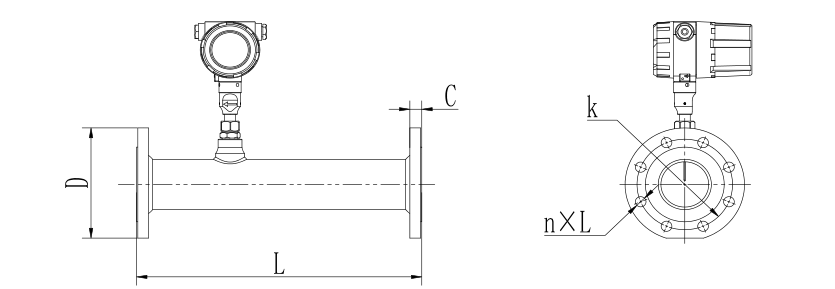

Standard Insertion type Pipeline type Hot tapped insertion type

(DN100~DN500) (DN10~DN200) (DN100~DN4000)

Dimensions

Standard insertion type Hot tapped insertion type

Pipeline type

Nominal Diameter | Flange Outer diameter |

Center Hole |

Screw Hole |

Screw Thread |

Sealing Face |

Flange Thickness |

Pipeline Length | |

DN | D | k | n×L | d | f | C | L | |

15 | 95 | 65 | 4×14 | M12 | 46 | 2 | 14 | 280 |

20 | 105 | 75 | 4×14 | M12 | 56 | 2 | 16 | 280 |

25 | 115 | 85 | 4×14 | M12 | 65 | 2 | 16 | 280 |

32 | 140 | 100 | 4×18 | M16 | 76 | 2 | 18 | 350 |

40 | 150 | 110 | 4×18 | M16 | 84 | 2 | 18 | 350 |

50 | 165 | 125 | 4×18 | M16 | 99 | 2 | 20 | 350 |

65 | 185 | 145 | 4×18 | M16 | 118 | 2 | 20 | 400 |

80 | 200 | 160 | 8×18 | M16 | 132 | 2 | 20 | 400 |

100 | 220 | 180 | 8×18 | M16 | 156 | 2 | 22 | 500 |

Technical Paramters

Power Supply | Supply Voltage | 24VDC/1.5A Allow residual ripple:0~100Hz, Upp = 30Mv,Uss<10mV Maximum noise:500Hz~10KHz ,Ueff = 2.0Mv or 85~265V AC |

Operating current | <650mA | |

Output | Output current mode | 4~20mA/ Fixed current output |

RS485 interface | Baud rate:1200/2400/4800/9600/19200 | |

Data:8 | ||

Check:None/Odd/Even | ||

Stop:1 | ||

RS232 interface | Baud rate:9600 ,Data:8,Check:None , Stop:1 | |

Communication protocol | MODBUS RTU |

Previous: No more

Next: No more