Typical application industry

◆ Sugar industry and brewing industry:

Extract juice, syrup, grape juice, etc., alcohol GL degree, ethane ethanol interface, etc.

◆Dairy industry:

Condensed milk, lactose, cheese, yoghurt, lactic acid, etc.

◆Construction and mining:

Slurry adjustment, coal (coal washing), potash, brine, phosphate, compound, limestone, copper, etc.

◆Oil refining:

Lubricating oil, fragrance, fuel oil, vegetable oil, etc.

◆Food processing:

Tomato juice, fruit juice, vegetable oil, starch milk, jam, etc.

◆Pulp and paper industry:

Black pulp, green pulp, paper pulp cleaning, evaporator, white pulp, caustic soda, etc.

◆Chemical:

Battery (sulfuric acid concentration, ratio) acid, caustic soda, urea, detergent, polymer, ethylene glycol, sodium chloride, sodium hydroxide, etc.

◆Petrochemical:

LNG, oil and gas washing, kerosene, lubricating oil, oil/water interface, etc.

◆Beverage processing:

Beer, soft drinks, fruit wine, instant coffee, malt, etc.

◆Pharmaceutical:

Concentration, fermentation, evaporation, proportioning, etc.

Technical characteristics

◆Direct density or concentration readings, engineering units that can be used include:

g/cm3, kg/m3, specific gravity, °Brix, °Baume, °Plato, °GL, percent solids, etc.

◆Suitable for flowing or still liquid

◆Suitable for density measurement of pipelines and tanks

◆Two-wire system adopts 4-20mA/Hart output

◆Three-wire system adopts 4-20mA/RS485 output

◆Adopt integrated structure, no moving parts

◆Standard industrial and hygienic process connection

◆The converter can be equipped with GPRS wireless remote transmission function

◆Built-in temperature sensor provides accurate temperature compensation

◆Built-in bubble level meter, it is easier to ensure the installation level

◆Online remote verification, digital local display

◆ Factory multi-point linear correction, higher accuracy

◆On-site recalibration: no standard reference source, no experimental calibration, no process interruption

◆The converter is compatible with three installation methods: wall-mounted, embedded and desktop

◆The converter uses touch screen display, the interface is more friendly

Technical Feature

Measuring Range | 1:0-1.5g/cm3 2:0-2g/cm3 3:0-3g/cm3 |

Accuracy class | A:±0.001 g/cm3 B:±0.005 g/cm3 C:±0.01 g/cm3 |

Ambient temperature effect: (every10℃) | 0.003×10-3 g/cm3 |

Static pressure effect (1kgf/cm) | 0.001×10-3 g/cm3c This systematic error is eliminated by calibration at static pressure |

Power effect | ±0.005 % calibrated range/V |

Process connection | SS tri-clamp SS flange |

Wetted Parts | 316L、Hastelloy C、Tantalum |

Non wetted parts | Filled fluid: Silicon (DC200/350,DC200/20,DC704) Syltherm800 or Glycerin |

Installation |

Pipeline or tank |

Temperature | Pt1000(-40-3000℃) |

Output | 2 wire 4-20mA/Hart |

Power |

24V DC |

Indicator | LCD |

Temperature | Ambient:-40-85℃ Process:-40-100℃ |

Response time | 0.2S |

Humidity | 0-100%RH |

Temperature | Automatic Pt1000 |

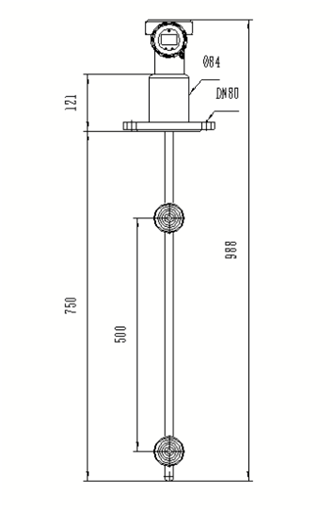

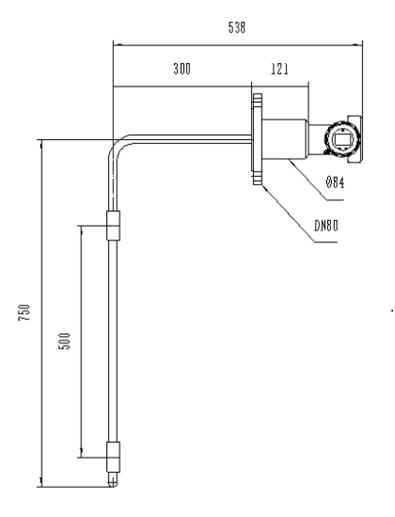

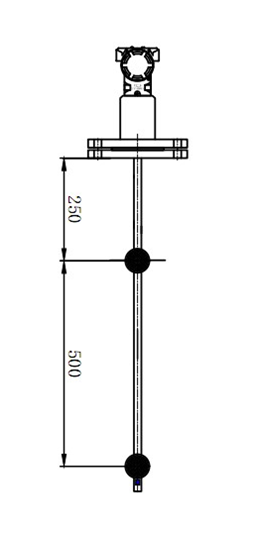

Figure and Outline:

Vertical mounted type

Side Mounted Type:

Two flange side mounted type

Order Code:

Code | Description |

HYDP301 | On line density concentration sensor |

Code | Material |

A | SS 316L |

C | Tantalum |

Z | Special request |

Code | Medium temperature |

N | 0~40℃ |

M | 0~80℃ |

H | 0~100℃ |

S | Special request |

Code | Density range |

X | 0~1g/cc |

B | 0~1.5g/cc |

E | 0~2g/cc |

Q | 0~3g/cc |

Code | Accuracy |

1 | 0.1% |

2 | 0.5% |

Code | Installation method |

Z | Vertical mounted |

W | Elbow side mounted |

S | 2 flange side mounted |

Code | Output |

A | 4~20mA with Hart |

D | RS485 |

Code | Pole length |

P | 750mm( Sensor distance500mm) |

T | Special request |

Previous: HYDM-303 On Line Vibrating Tube density Meter

Next: Fork Density Meter